The sustainable airplane seat of the HAIRMATE project scores the most demanding frontal 10G crash test

The sustainable airplane seat of the HAIRMATE project scores the most demanding frontal 10G crash test

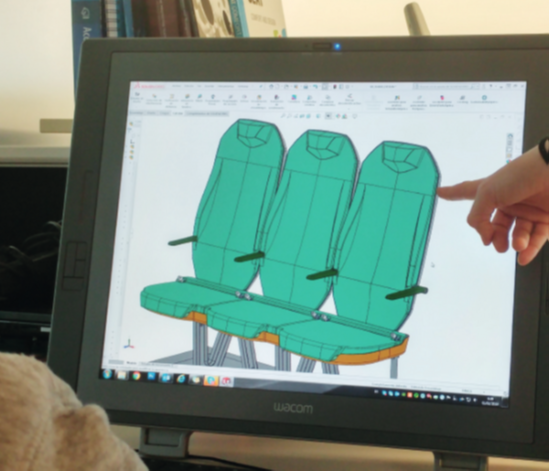

The European HAIRMATE project, led by Leitat together with Fraunhofer, the University of Girona (UDG) and ALPEX, has allowed the design and manufacture of a sustainable, lightweight, low maintenance and industrializable seat for the future of European Aviation.

After 5 years of work, the European project HAIRMATE, financed by the European Union and led by Leitat, together with the Fraunhofer technology center, has developed new sustainable aeroplane seats that incorporate materials and manufacturing processes based on the use of carbon fibres with the application of a sustainable resin whose design has been carried out by Leitat and TIPD (Technology Integration and Product Development), which has also had the support of ALPEX for the manufacture of moulds. This collaboration has allowed the manufacture of two seat prototypes, one of which has obtained surprising results in the first resistance tests, reaching 10G.

The HAIRMATE project has also involved the participation of the University of Girona (UDG), by carrying out and coordinating the tests, in collaboration with the DTC (Dynamic Test Center AG).

The prototype manufactured to carry out the test not only withstood 10.68G, but also the condition of the seat after the test was good enough for a second test with the same characteristics.

The seat designed within the framework of the HAIRMATE project is made of WCM and SMC parts with a special design created by Leitat and FRAUNHOFER and produced using a manufacturing process and joining technology patented by FRAUNHOFER. It is a sustainable, lightweight, low-maintenance and industrializable seat for the future of European aviation, as opposed to the usual tubular structure based on carbon fiber with titanium joints, which is more expensive.

The consortium is currently seeking funding at the European level to continue the development of the technology and to be able to make this prototype available soon for future vehicles designed and manufactured in the European Union for land, sea and air.