New system degrading and removing harmful substances from industrial wastewaters

Current costs for industrial wastewater treatment in Europe are already an economic burden and are expected to rise. The costs are restricting the growth of the European production sector, especially in water scarce areas where there is a pressing need to reuse water. OxFloc aims to reduce treatment costs while offering modular installation and application engineering at a price below comparable State-of-the-Art processes.

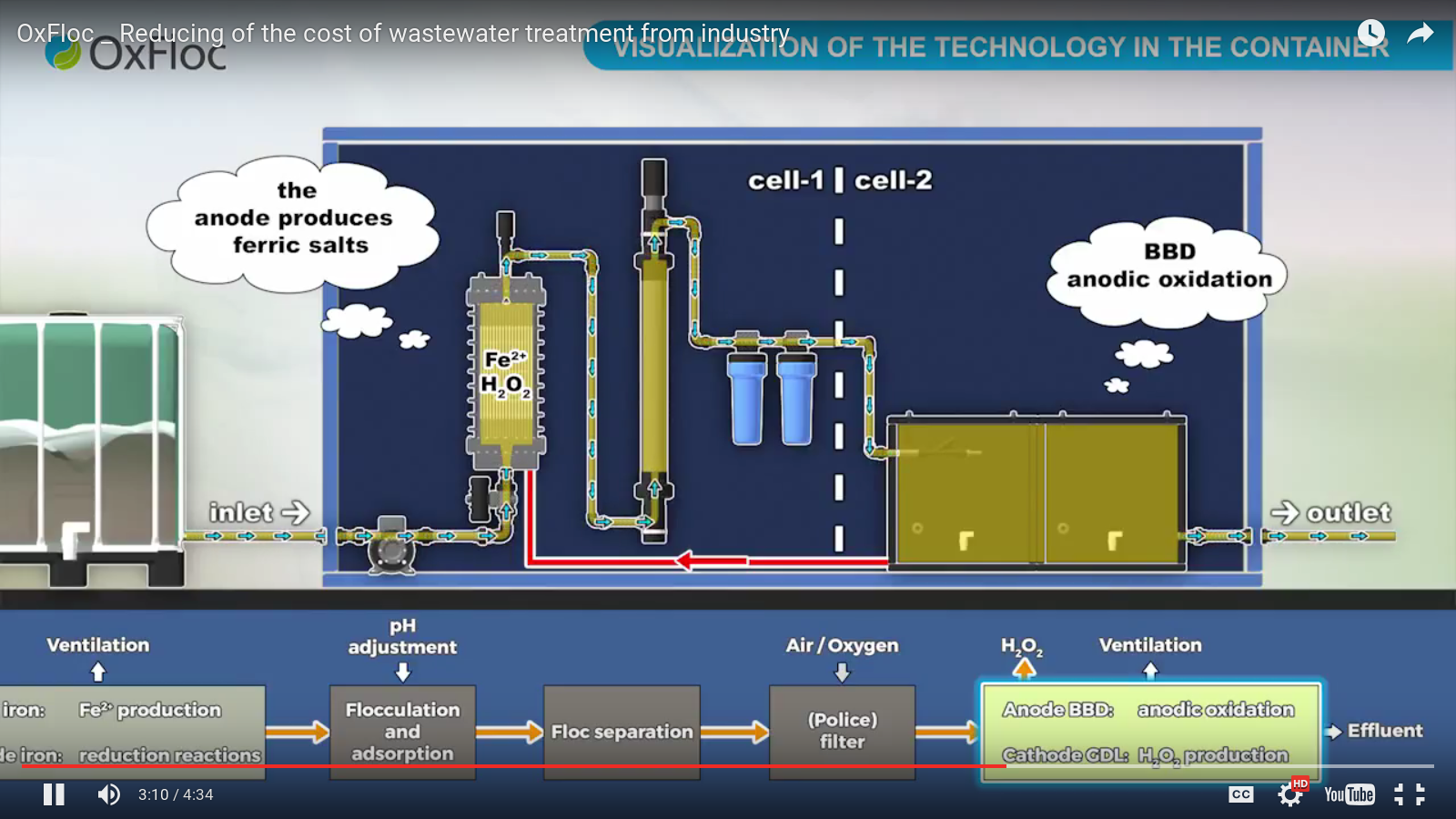

OxFloc systems will have a quantifiable superior environmental benefit, a smaller plant footprint, lower operation costs, and enable water recycling as they work without salt-carrying chemicals. Not all industrial wastewaters are the same, but many carry a mix of toxic chemicals, non-biodegradable components and hormones, e.g. tensides, flame resistants, pharmaceuticals, pesticides and heavy metals. Therefore, industrial effluents need significant treatment before they can be discharged to a municipal wastewater treatment plant. Typically the pollutants exist with suspended particles, requiring a clearing pretreatment which increases cost and energy consumption of current treatments. Our system solves this problem by combining particle removal and adsorption with advanced oxidation.

The OxFloc system is a one-stage combined flocculation-oxidation process that needs no chemicals because electrolytic production of the iron catalyst, as well as hydrogen peroxide, takes place in the reactor itself. It is an integrated system capable of degrading and removing both dissolved and suspended harmful substances from industrial wastewaters using only electrical energy. It will be fully compatible with power from renewable energy sources, conventional supply or from smartpower grids balancing supply and demand of electrical energy.

More information about the project here.